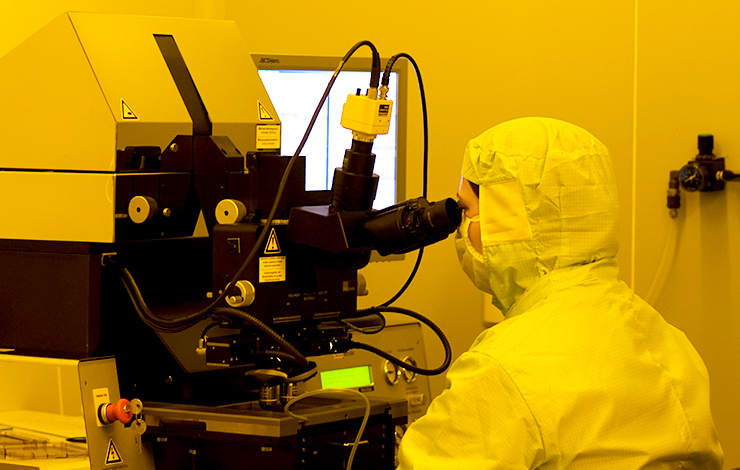

Xplore Micro Compounder 5

The Xplore Micro Compounder 5 is an extruder designed especially for R&D, it allows batches from 2 mL to 5 mL.

It has a pneumatic front feeder, to load the chamber and intermeshing screws to produce fast and reproducible results. The chamber has a reflow design which allows the possibility of using two different materials and guarantee a good mixture. It also has three heating zones, each zone has two heaters to assure a uniformly heating. The equipment allows to control the heating zones and create heating gradients.

The extruder can be controlled via touch screen or with a computer by an extended rheological software. This rheological software offers a very accurate instrument measure of the melt and is based on modeling the rheological process in the conical, twin-screw driver. The analysis relates the measured vertical force in our extruder with the actual melt torque, the estimated shear viscosity and the corresponding estimated average shear rate and shear stress. This information is essential for correct upscaling.

|

Batch size |

2 to 5 mL |

|

Maximum Temperature |

450 ℃ |

|

Maximum torque/screw |

6 Nm |

|

Connectivity |

USB |

|

Materials |

Polymers in pellets form. Possibility of using nanotubes and nanowires. |