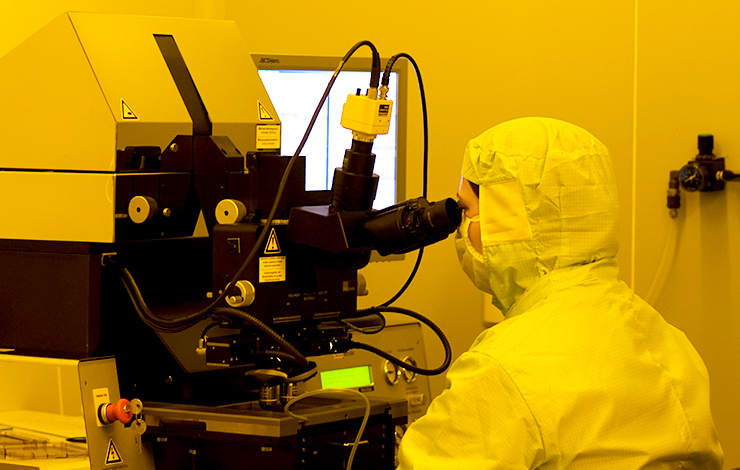

3D Printer - Form 2

Location: Lab 0.2

Responsible: Sara Silvestre

Description:

The Form 2 is a stereolithography (SLA) 3D printer. Stereolithography is an additive manufacturing - commonly referred to as 3D printing - technology that converts liquid materials into solid parts, layer by layer, by selectively curing them using a light source in a process called photopolymerization. SLA is widely used to create models, prototypes, patterns, and production parts for a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

Specifications:

|

Technology

|

Stereolithography (SLA)

|

|

Weight

|

13 Kg

|

|

Build Volume

|

45 × 145 × 175 mm

|

|

Operating Temperature

|

Auto-heats to 35° C

|

|

Temperature Control

|

Self-heating Resin Tank

|

|

Laser Specifications

|

EN 60825-1:2007 certified

405nm violet laser

250mW laser

|

|

Laser Spot Size (FWHM)

|

140 microns

|

|

Connectivity

|

Wifi, Ethernet and USB

|

|

Optical Path

|

Protected

|

|

Layer Thickness (Axis Resolution)

|

25, 50, 100 microns

|

|

Supports

|

Auto-Generated Easily Removable

|

|

Material Properties

|

Methacrylate Photopolymer Resin

|

|

Supported file types

|

STL and OBJ

|

|

Print Materials

|

Black resin https://formlabs.com/media/upload/Black-SDS.pdf White resin https://formlabs.com/media/upload/White-SDS.pdf High Temp resin https://formlabs.com/media/upload/HighTemp-SDS.pdf Durable resin https://formlabs.com/media/upload/Durable-SDS-201.pdf Flexible resin https://formlabs.com/media/upload/Flexible-SDS_eSMv2T6.pdf |