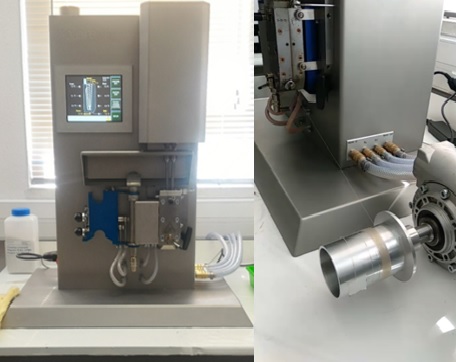

Extruder - Twin-screw micro-compounder + Pulling system for fibres

Responsible: Rui Igreja

Technical Specifications:

- Abrasion resistant barrel (hardness 60 HRc), coating hardness 2000 Vickers

- Barrel and screws chemically resistant between pH 0 – 14

- Batch volume: 5 ml (Vari-BatchTM 2 or 5 ml)

- Vertical barrel, fluid-tight

- Heated by 8 thermo cartridges and controlled by 7 thermo couples (temperature gradient)

- Temperature control: in the melt and 2x3 barrel heating zones

- Detachable conical screws, fully intermeshing (Hardness 54 HRc), coating hardness: 1000 Vickers

- Maximum operating temperature: 400 °C (optionally 450 °C)

- Easy to clean with dedicated cleaning cycle

- Heating time (from 20 to 240 °C): 10 min

- Cooling time (from 240 to 80 °C): with cooling water in less than 10 min, with air in less than 35 min

- Acquisition of rheological data (screw torque in melt, melt viscosity, shear rate and shear stress)

- Maximum vertical force: 5 kN

- Screw speed: continuously variable 1 - 400 RPM

- Hopper volume: 5 ml

- Supply voltage: 208 - 240 V AC, others on request

- Main drive: DC controlled, 550 Watt

- Computer control via: USB port

- Maximum torque: 6 Nm per screw

- Overall dimensions (h x b x d): 80 x

- Abrasion resistant barrel (hardness 60 HRc), coating hardness 2000 Vickers

- Barrel and screws chemically resistant between pH 0 – 14

- Batch volume: 5 ml (Vari-BatchTM 2 or 5 ml)

- Vertical barrel, fluid-tight

- Heated by 8 thermo cartridges and controlled by 7 thermo couples (temperature gradient)

- Temperature control: in the melt and 2x3 barrel heating zones

- Detachable conical screws, fully intermeshing (Hardness 54 HRc), coating hardness: 1000 Vickers

- Maximum operating temperature: 400 °C (optionally 450 °C)

- Easy to clean with dedicated cleaning cycle

- Heating time (from 20 to 240 °C): 10 min

- Cooling time (from 240 to 80 °C): with cooling water in less than 10 min, with air in less than 35 min

- Acquisition of rheological data (screw torque in melt, melt viscosity, shear rate and shear stress)

- Maximum vertical force: 5 kN

- Screw speed: continuously variable 1 - 400 RPM

- Hopper volume: 5 ml

- Supply voltage: 208 - 240 V AC, others on request

- Main drive: DC controlled, 550 Watt

- Computer control via: USB port

- Maximum torque: 6 Nm per screw

- Overall dimensions (h x b x d): 80 x