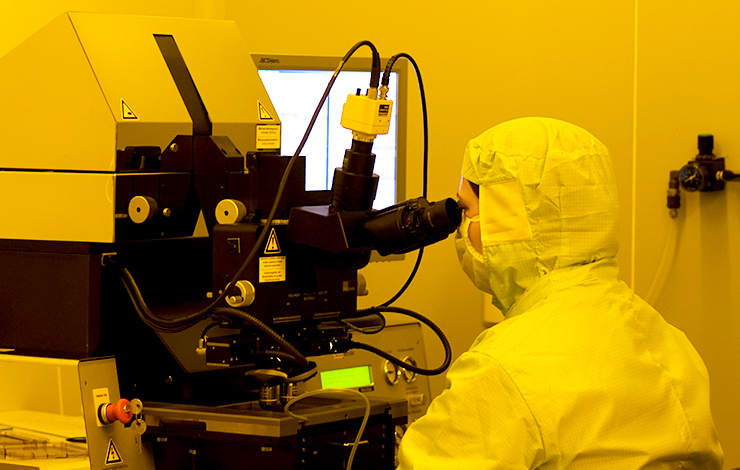

Multicoater LRC

Location: Fun Paper Lab

Responsible: Cristina Gaspar

Description:

The Multicoater combines all four important techniques into one robotic and modular platform, eliminating the need to install individual equipment for inkjet printing, electrospinning, (ultrasonic) spray coating and dip coating. It is a versatile equipment, plug and play and cost-effective.

Main features:

● Easy-to-use software

● XYZ movement of robotic arm - complex and large area films and patterns can be made

● Modular design - plug and play

● Cost- and space-effective

● Process automation

● High throughput and roll-to-roll capability

● Pre- and post- coating accessories

● Stationary or spinning substrate (holder)

● Custom design, e.g controlled atmosphere

● High throughput experiments

Specifications:

Inkjet module

▪ Dual cartridge

▪ Disposable Cartridges

▪ Thermoelectric nozzle

▪ 96 dpi

▪ 12 Nozzles/cartridge

▪ 85 microns nozzle size

Ultrasonic spray coating module

▪ Small homogeneous droplets

▪ Control over droplet size

▪ Micro volumes can be dispensed

▪ Changeable syringes

▪ More than one independently driven syringe option

▪ Nozzle adjustable by up to 180 °

Electrospinning module

▪ Flexible mats and membranes (standalone or on substrates)

▪ Nanoscale to micro porosity

▪ High surface to volume ratio

▪ Nano/micro encapsulation

▪ Hybrid and composite materials

▪ Two syringe system

Dip coating module

▪ Controlled speed and deposition time

▪ Suitable for layer by layer/monolayer assembly

▪ Protective coating

▪ Complete coating on 3D objects

▪ Chemical bath deposition

Responsible: Cristina Gaspar

Description:

The Multicoater combines all four important techniques into one robotic and modular platform, eliminating the need to install individual equipment for inkjet printing, electrospinning, (ultrasonic) spray coating and dip coating. It is a versatile equipment, plug and play and cost-effective.

Main features:

● Easy-to-use software

● XYZ movement of robotic arm - complex and large area films and patterns can be made

● Modular design - plug and play

● Cost- and space-effective

● Process automation

● High throughput and roll-to-roll capability

● Pre- and post- coating accessories

● Stationary or spinning substrate (holder)

● Custom design, e.g controlled atmosphere

● High throughput experiments

Specifications:

Inkjet module

▪ Dual cartridge

▪ Disposable Cartridges

▪ Thermoelectric nozzle

▪ 96 dpi

▪ 12 Nozzles/cartridge

▪ 85 microns nozzle size

Ultrasonic spray coating module

▪ Small homogeneous droplets

▪ Control over droplet size

▪ Micro volumes can be dispensed

▪ Changeable syringes

▪ More than one independently driven syringe option

▪ Nozzle adjustable by up to 180 °

Electrospinning module

▪ Flexible mats and membranes (standalone or on substrates)

▪ Nanoscale to micro porosity

▪ High surface to volume ratio

▪ Nano/micro encapsulation

▪ Hybrid and composite materials

▪ Two syringe system

Dip coating module

▪ Controlled speed and deposition time

▪ Suitable for layer by layer/monolayer assembly

▪ Protective coating

▪ Complete coating on 3D objects

▪ Chemical bath deposition