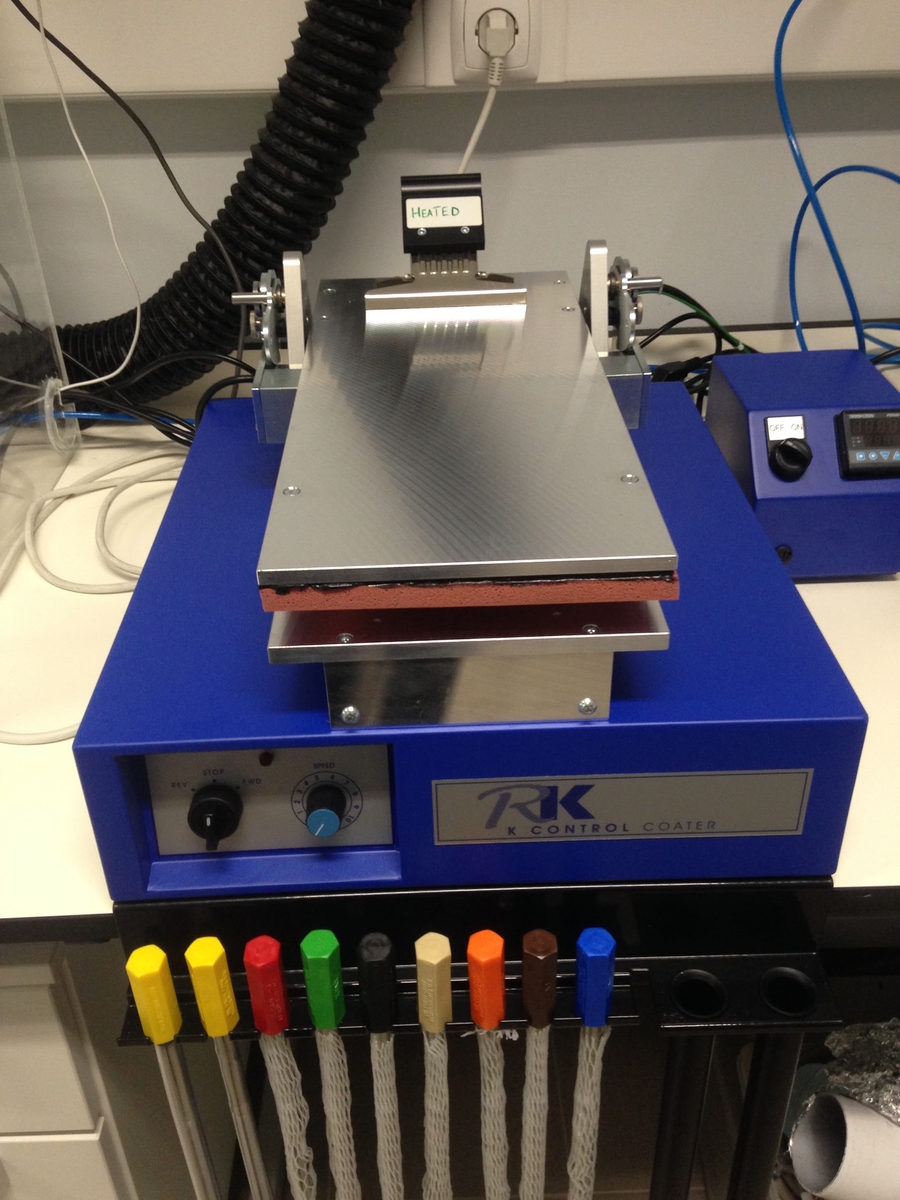

K101 Control Coater System

Location: Fun Paper Lab

Responsible: Cristina Gaspar

Description:

The K Control Coater is widely used for the application of paints, varnishes, adhesives, liquid printing inks and many other surface coatings to produce quick, accurate and repeatable samples. These may then be used for quality control and presentation purposes, R&D, computer colour matching data etc. These are elements vital to a company’s success in the modern world.

Meter bars provide the simplest method of applying accurate, repeatable surface coatings on to most substrates. A meter bar is manufactured by winding precision drawn stainless steel wire onto a stainless steel rod, resulting in a pattern of identically shaped grooves. These grooves then precisely control the wet film thickness. Close wound bars produce a coating thickness from 4 to 120μm. Higher coating weights up to 500μm can be obtained using spirally wound bars. A three-part melinex/foam/rubber coating bed is supplied as standard. Vacuum, magnetic, heated and glass beds are also available.

Specialised coating beds are available to ensure the best possible results for particular applications. Each is suggested for different types of substrate.

Vacuum beds

TYPE A: Recommended when coating onto a delicate or stretchy substance such as aluminium foil or polythene.This is a rubber faced bed connected to a vacuum pump which holds the material perfectly flat. Vacuum is applied from the edges of the substrate only.

TYPE B:A smooth aluminium faced bed with vacuum applied via multiple holes over the entire substrate surface. This is suitable for more rigid substances, and especially recommended when coating on to paint charts with gap applicators.

Magnetic bed

For use when coating on to a magnetic substrate such astin plate, to ensure a totally flat surface. Permanent magnets are used, which are operated by an on/off key.

Heated bed

Specialised for applying coatings which require heating.Examples include hot melts and electrographic inks. Thebed has a smooth aluminium face which can be heatedup to 150 degrees and is set by a digital temperaturecontroller.

Glass bed

This provides a perfectly flat surface which is very easilycleaned. It is especially recommended for gapapplicators which provide a hard surface.

Specifications:

▪ Controlled speed and pressure ensures repeatable results

▪ Coating by wire wound bars or gap applicators

▪ Two models offer coating areas of up to 170 x 250 mm or 325 x 250 mm

▪ Multiple coatings in one operation for comparison purposes

▪ Standard coating speeds infinitely variable between 2 and 15 m/min

▪ K101 bars:

o K101 Bar No.0 White/4 micron

o K101 Bar No. 1 Yellow/6 micron

o K101 Bar No. 2 Red/12 Micron

o K101 Bar No. 3 Green/24 Micron

o K101 Bar No. 4 Black/40 Micron

o K101 Bar No. 5 Horn/50 Micron

o K101 Bar No. 6 Orange/60 Micron

o K101 Bar No. 7 Brown/80 Micron

o K101 Bar No. 8 Blue/100 Micron

▪ Special purpose coating beds:

o K101 Heated Bed & Temp Control 220/240 V

▪ 4 insulation spacers & screws

▪ 2 spacer plates

▪ 150 C max continuous temperature

o K101.21 K101 Aluminium Vacuum Bed

▪ Vacuum applied via multiple holes

▪ Recommended for rigid substrates

▪ Type B

o K101.27 K101 Heated Vacuum Bed

▪ Aluminium bed with a vacuum slot

▪ Heated - max 150 C

▪ 230 Volts

▪ Vacuum Pump Assembly (220 volt)

● Comprising:- Vacuum pump,fittings & tube

● pump spec: Vacuum = 25.5"Hg max

● 220/240V, 1.9 / 2.2A, 50Hz

o K101.23 K101 Magnetic Bed Assembly (REQUIRES SPECIAL NON MAGNETIC BARS)

▪ Footprint: All 400 x 450mm

▪ Weight: 27 kg

▪ Drives: All available with electrical drive of 110/220 volts or with a pneumatic drive suitable for hazardous areas.

Responsible: Cristina Gaspar

Description:

The K Control Coater is widely used for the application of paints, varnishes, adhesives, liquid printing inks and many other surface coatings to produce quick, accurate and repeatable samples. These may then be used for quality control and presentation purposes, R&D, computer colour matching data etc. These are elements vital to a company’s success in the modern world.

Meter bars provide the simplest method of applying accurate, repeatable surface coatings on to most substrates. A meter bar is manufactured by winding precision drawn stainless steel wire onto a stainless steel rod, resulting in a pattern of identically shaped grooves. These grooves then precisely control the wet film thickness. Close wound bars produce a coating thickness from 4 to 120μm. Higher coating weights up to 500μm can be obtained using spirally wound bars. A three-part melinex/foam/rubber coating bed is supplied as standard. Vacuum, magnetic, heated and glass beds are also available.

Specialised coating beds are available to ensure the best possible results for particular applications. Each is suggested for different types of substrate.

Vacuum beds

TYPE A: Recommended when coating onto a delicate or stretchy substance such as aluminium foil or polythene.This is a rubber faced bed connected to a vacuum pump which holds the material perfectly flat. Vacuum is applied from the edges of the substrate only.

TYPE B:A smooth aluminium faced bed with vacuum applied via multiple holes over the entire substrate surface. This is suitable for more rigid substances, and especially recommended when coating on to paint charts with gap applicators.

Magnetic bed

For use when coating on to a magnetic substrate such astin plate, to ensure a totally flat surface. Permanent magnets are used, which are operated by an on/off key.

Heated bed

Specialised for applying coatings which require heating.Examples include hot melts and electrographic inks. Thebed has a smooth aluminium face which can be heatedup to 150 degrees and is set by a digital temperaturecontroller.

Glass bed

This provides a perfectly flat surface which is very easilycleaned. It is especially recommended for gapapplicators which provide a hard surface.

Specifications:

▪ Controlled speed and pressure ensures repeatable results

▪ Coating by wire wound bars or gap applicators

▪ Two models offer coating areas of up to 170 x 250 mm or 325 x 250 mm

▪ Multiple coatings in one operation for comparison purposes

▪ Standard coating speeds infinitely variable between 2 and 15 m/min

▪ K101 bars:

o K101 Bar No.0 White/4 micron

o K101 Bar No. 1 Yellow/6 micron

o K101 Bar No. 2 Red/12 Micron

o K101 Bar No. 3 Green/24 Micron

o K101 Bar No. 4 Black/40 Micron

o K101 Bar No. 5 Horn/50 Micron

o K101 Bar No. 6 Orange/60 Micron

o K101 Bar No. 7 Brown/80 Micron

o K101 Bar No. 8 Blue/100 Micron

▪ Special purpose coating beds:

o K101 Heated Bed & Temp Control 220/240 V

▪ 4 insulation spacers & screws

▪ 2 spacer plates

▪ 150 C max continuous temperature

o K101.21 K101 Aluminium Vacuum Bed

▪ Vacuum applied via multiple holes

▪ Recommended for rigid substrates

▪ Type B

o K101.27 K101 Heated Vacuum Bed

▪ Aluminium bed with a vacuum slot

▪ Heated - max 150 C

▪ 230 Volts

▪ Vacuum Pump Assembly (220 volt)

● Comprising:- Vacuum pump,fittings & tube

● pump spec: Vacuum = 25.5"Hg max

● 220/240V, 1.9 / 2.2A, 50Hz

o K101.23 K101 Magnetic Bed Assembly (REQUIRES SPECIAL NON MAGNETIC BARS)

▪ Footprint: All 400 x 450mm

▪ Weight: 27 kg

▪ Drives: All available with electrical drive of 110/220 volts or with a pneumatic drive suitable for hazardous areas.