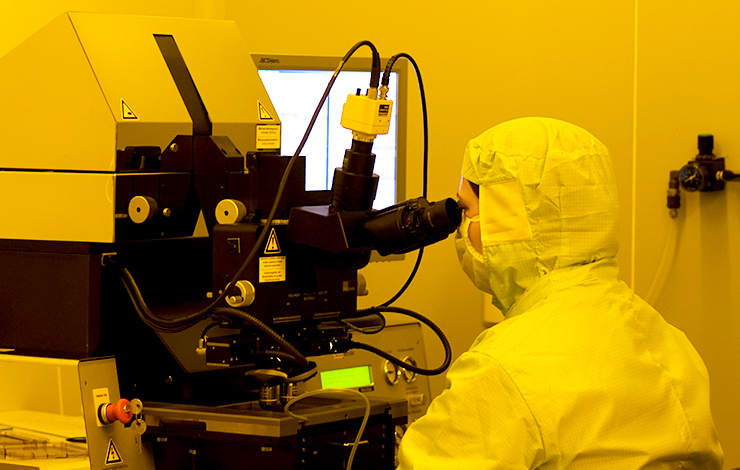

Screen Stencil printer - C920 Aurel Automation

Responsible: Cristina Gaspar

Description:

AUREL Mod. C920 is a high precision free stand screen/stencil printing machine and meets the requirements for high quality automatic printing on large areas. The main application in the electronic are thick film, SMT, polymeric pastes, solar cells.

Mod. C920 can be equipped with a vision system and two TV cameras to simplify the alignment operation between screen/stencil and substrate.

Applications:

AUREL Mod. C920 ia a free stand screen-stencil printer with cabinet and security cover that can print area up to 350 x 400 mm, assuring uniform deposition from corner to corner.

Some applications for electronic and general industrial purposes are:

● Thick film pastes

● Solder paste for SMT

● Glue, adhesive, resin

● Polimeryc pastes

● Solder resist

● Flexible Foils

● Membrane switch panel

● Solar cel

Controls:

● The machine is PC controlled and allows a great deal of flexibility on all functions

● Touch screen monitor with user friendly interface

● Print and flood, alternating print and after print delay

● Programmable printing speed

● Machine diagnostic

● Machine hood & parts lifting and locking. Setting up, and all parameters controls & storage

Features:

● Double squeegee head

● Speed & Pressure digital controll

● Automatic shuttle table

● Large printing areab (up to 350 x 400 mm)

● Print & Flood, Print & Print, Print + Print

● Contact and off contact

● Printing head dc motor drive

● Continuously adjustment of the printing speed and stroke

● Precision X-Y-Theta work table for accurate substrate alignment

● Substrate hold-down by vacuum

● Vacuum pump included

● All movements on precision ball bearing linear slides

● High precision print head with micrometric height and down stop adjustment

Vision (as option):

● Pro Align Vision system

● Two TV cameras

● Graphic overlapping of the memorized fiducials on the “life” image

● Accurate alignment by micrometers

● Programmable tolerance to achieve very high precision (for fine line and fine pitch)