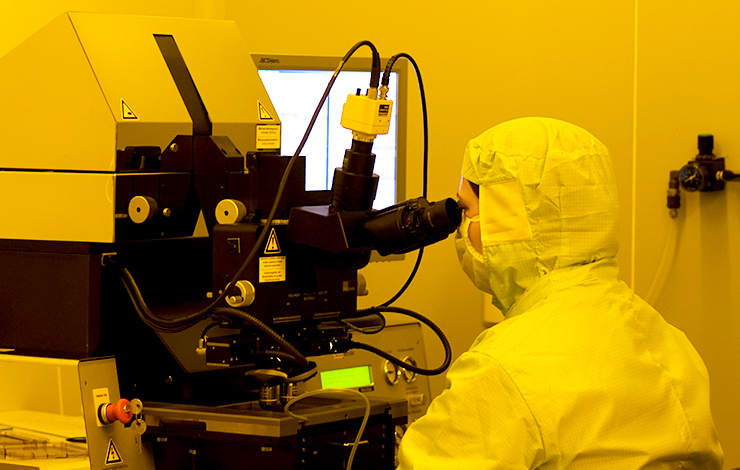

Speciality Coating PDS-2010 Parylene coater

Location: Clean room CEMOP – thin-film deposition lab

Responsible: Joana Pinto

Description: CVD system for Parylene conformal coatings. Parylene coatings are pinhole-free polymer coatings that provide high-value surface treatments properties such as excellent moisture, chemical and dielectric barrier properties, thermal an UV stability and dry film lubricity. It polymerises at relatively high pressures, above 10 mtorr (1.3 Pa) at room temperature, and all sides of the available surfaces in the deposition chamber are impinged uniformly by the gaseous monomer. Typical thickness between 100 nm to 10 µm.

Specifications:

- Available dimers (at CENIMAT): DPX-C (for Parylene-C) and DPX-N (for Parylene-N)

- Vacuum – 1 primary vacuum pump, with exhaust

- Cold trap connected to a Mechanical chiller

- Deposition Chamber Dimensions: 31 cm (diameter) x 31 cm height suable area

- Dimer capacity (maximum load): 125 g, meaning a maximum 50 µm polymer thickness

- Evaporation Chamber – Maximum temperature until 200 °C

- Pyrolysis tube – standard temperature of 690 °C

- Deposition Chamber – Room temperature

- Controls - Computerized sequencing using microprocessor temperature and process controllers. Automatic and semi-automatic operation with fault condition and end-of-run monitoring for controlled shutdown sequence.

Responsible: Joana Pinto

Description: CVD system for Parylene conformal coatings. Parylene coatings are pinhole-free polymer coatings that provide high-value surface treatments properties such as excellent moisture, chemical and dielectric barrier properties, thermal an UV stability and dry film lubricity. It polymerises at relatively high pressures, above 10 mtorr (1.3 Pa) at room temperature, and all sides of the available surfaces in the deposition chamber are impinged uniformly by the gaseous monomer. Typical thickness between 100 nm to 10 µm.

Specifications:

- Available dimers (at CENIMAT): DPX-C (for Parylene-C) and DPX-N (for Parylene-N)

- Vacuum – 1 primary vacuum pump, with exhaust

- Cold trap connected to a Mechanical chiller

- Deposition Chamber Dimensions: 31 cm (diameter) x 31 cm height suable area

- Dimer capacity (maximum load): 125 g, meaning a maximum 50 µm polymer thickness

- Evaporation Chamber – Maximum temperature until 200 °C

- Pyrolysis tube – standard temperature of 690 °C

- Deposition Chamber – Room temperature

- Controls - Computerized sequencing using microprocessor temperature and process controllers. Automatic and semi-automatic operation with fault condition and end-of-run monitoring for controlled shutdown sequence.