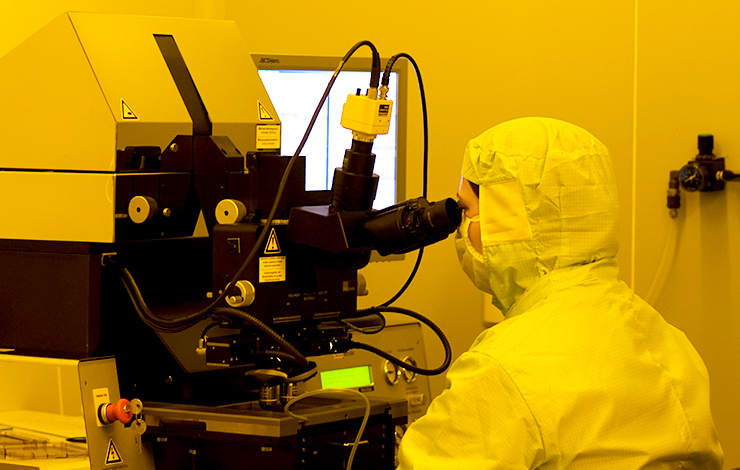

Clean Room - Yellow zone

Description: Class 1000 room, equipped with all the tools necessary to perform lithographic processes in microelectronics.

Karl Suss MA6 mask aligner

• 350 W Hg lamp (OSRAM HBO 350 W/S)

• Typical operation in the spectral range of 350-450 nm

• Band-pass i-line filter (restricts radiation to 365 nm) also available

• Mask size up to 5x5”

• Wafer size up to 150 mm

• Soft, hard, low vacuum and vacuum contact, as well as proximity exposure

• Sub-micron exposure resolution (≈0.5 µm), alignment resolution ≈1 µm

• Enhanced Image Storage System (EISS) software for improved alignment capabilities

Alcatel GIR300 reactive ion etching

• Process gases: SF6, CF4, Ar, O2

• Substrate size up to 10x10 cm

• Rf generator power up to 600 W

Spin-coaters

• Headway Research PWM32 for positive photoresist (max. substrate size 10x10 cm, max. rotation speed ≈10000 rpm)

• KarlSuss RC5 for negative photoresist (max. substrate size 10x10 cm, max. rotation speed ≈10000 rpm)

Hotplates

• Fisher Scientific Isotemp (temperatures up to 550 °C, mostly for positive photoresist baking)

• Torrey Pines HS40A-2 programmable hotplate (temperatures up to 400 °C, mostly for SU-8 baking and device annealing

Optical microscope – Leitz Laborlux 12 ME ST

• Magnification: ocular 10x; objectives 10x, 20x, 50x and 100x

• Color TV camera and image or movie acquisition to computer

• Integrated feature measurement tool (down to ≈10 µm)